Our history is linked to the figure of the company founder, Santos Morte, who began working in a workshop dedicated to the manufacture of metal parts in the 1960s.

Over time, he discovered that ceramic plants demanded extrusion dies that not all workshops were capable of manufacturing, as they required a special talent.

Being young and eager to improve himself, Santos started his own specialised workshop for manufacturing extrusion dies for the ceramic industry in 1975.

In the early 1990’s, with the incorporation of Marcos Morte, the first CAD-CAM workstation was installed, which was a turning point in the use of technology in the design area.

Over the years, we have continued to add new software for different applications, and currently have:

- CREO Parametric, for the 3D design of all our products

- ESPRIT for CAM machining

- ANSYS for Finite Element analysis, used to perform mechanical and thermal studies

- WINDCHILL, for lifecycle management of company projects

- SPYRO, ERP for integrated company management.

The constant search for innovative solutions in the design of our products has led us to protecting all our research effort.

The different research and development projects that we have investigated in several areas, such as the TM-EF die, the inner steel, the Modular Coreholder System and the EXTRUM system, have led to patents being approved in several countries and have meant a turning point in the concept of dies with both national and international recognition.

Due to the expansion of the company, we moved to our current location on a plot of land of 23,000m² in 2004. The new plant houses a wide range of state-of-the-art machinery to control the entire production process within the company; thus improving the quality and the service of our products.

In 2005 we added the oxycut and plasma cutting line, as well as the new heat treatment line, for controlling at any given moment the tempered hardness of certain die components ensuring high standards of quality and optimum delivery times.

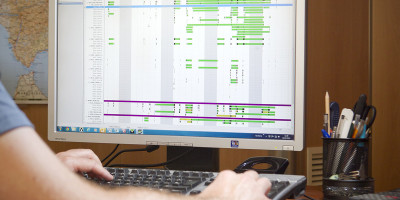

In 2006, following a thorough analysis, we chose a control system capable of integrating purchasing, sales, production, quality and accounting into a single management tool.

This system allows cross-analysis of many aspects related to customers, suppliers, projects, machinery and provides a thorough understanding of the reality of the business, the needs of our customers and “on line” quality control and production.

Initially, we produced to meet the demands of the Spanish market. However, since 2000, we have undertaken individual operations to meet the demands of foreign ceramic companies.

Our international presence has strengthened over the years, which has encouraged us to participate in international fairs and conventions to improve our image and recognition in the world. Nowadays, our products are present in more than 30 countries.

Our international growth is based on signing representation agreements with reputable companies in the countries where we work, establishing a close relationship between MORTE and our customers, and offering flexible and highly specialised service.