DIFFERENCES BETWEEN STEEL AND CHROME

Interview with Marcos Morte

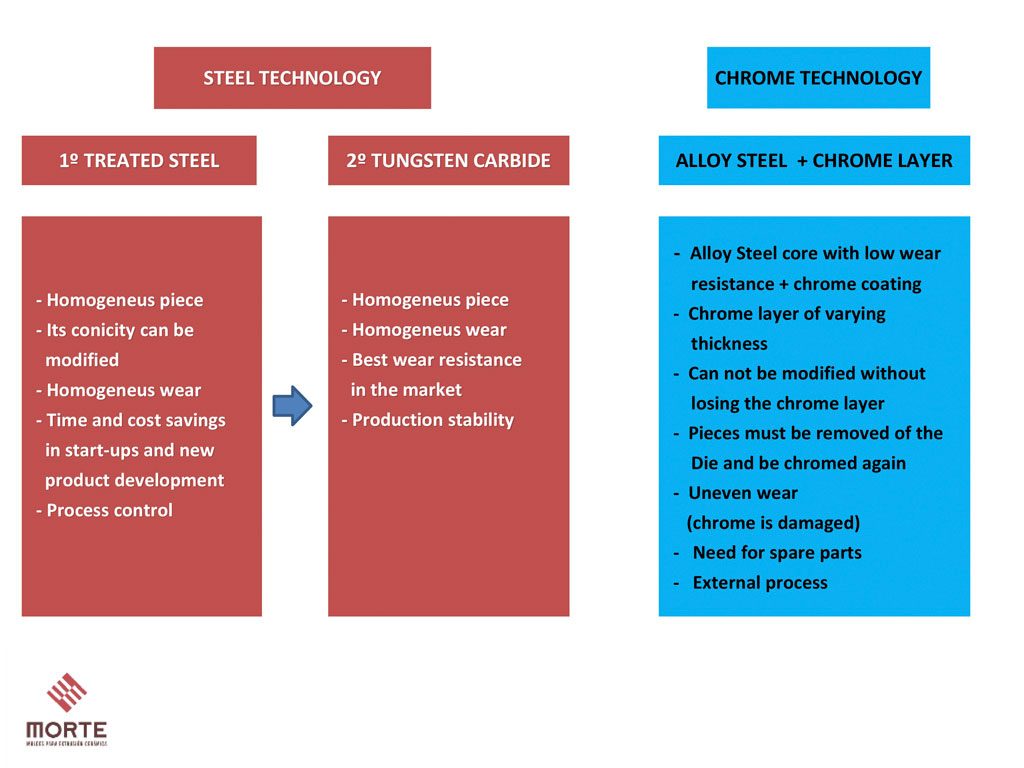

Nowadays in the ceramic industry the use of Treated Steel and Hard Chrome in extrusion Dies is widespread. For this reason, over the last few years, there has been talk about two rather antagonistic technologies present in the sector: those of Treated Steel and Hard Chrome.

1st) Can you give us a general overview of the differences between Treated Steel and Hard Chrome?

The key difference lies in the composition and properties of the two materials.

Firstly, Treated Steel is a ledeburite steel with high chromium content, which is highly wear-resistant and dimensionally stable after hardening (hardness of 62-64 HRC).

Meanwhile, Hard Chrome is applied using an electrolytic treatment through which parts are coated with a chrome film (hardness of 70 HRC), which varies in thickness (usually 0.2 – 0.4 mm), over an alloy steel core or base whose wear-resistance is very low (hardness of 30-35 HRC).

2nd) What are the advantages of using Treated Steel?

The main advantage is how easy it is to modify Treated Steel. As it is a homogeneous piece, its conicity, tilt, etc. can be modified without altering its abrasion resistance.

Conversely, as Hard Chrome is applied onto a core or base piece, the conicity of this piece cannot be changed, as to do so, the chrome layer would disappear, leaving the core exposed. This means that in order to undergo any kind of modification, it would be necessary to subject the piece to chrome coating again.

Another significant advantage lies in the time and cost savings in the setting ups or development of new products.

At MORTE, we are aware of the considerable costs to our customers inherent in stopping production. Thus, when tests are ongoing, it is necessary to take quick decisions and perform the necessary corrective measures as soon as possible. This is where Treated Steel comes in.

When the Die is put into production, the necessary checks are performed to identify if any changes or modifications are required. If needed, the execution of the corrections on the Die will be fast.

However, if the Die is manufactured in Hard Chrome, any modification will be drawn out over time, as the pieces need to be removed from the Die to be chrome coated again. This leads to notable delays in delivery times, which consequently reduces margin of manoeuvre.

3rd) Is there any other relevant aspect that you want to highlight?

In our experience, one key factor is process control.

For over 30 years here at MORTE we have specialised in the thermal treatment of the Treated Steel, as we have our own facility which enable us to fully control the hardening to be done on the pieces.

In this heat treatment, steel is heated to austenizing temperatures before being cooled rapidly. The aim is to achieve a transformation that provides a hard and resistant martensitic structure. Consequently, the quality that we offer in our Dies is always guaranteed.

By contrast, when these pieces need to be chrome coated, the process needs to be outsourced, thereby losing control over it.

This situation can become a problem, since if the application of Hard Chrome is not done correctly, the chrome layer may be damaged, leading to unbalanced wear as noted before.

4th) The advantages in terms of setting ups and development of new products are clear, but regarding Dies for mass production, what would you recommend to ceramists?

At MORTE, we have always bet for the use of Treated Steel with the end goal that once the Die works properly with this material and the product for our customer is correct, the parts of the Die more exposed to wear, e.g. cores and frames, being replaced with other ones manufactured in our own tungsten carbide formula, MOR 05. This material presents the best wear-resistance on the market and shows a much higher level of profitability than Hard Chrome.

Therefore, these parts do not have to be replaced for months, thus stabilising production and bringing tranquillity to ceramists, as they can forget about changes in dimensions and weight of their products for a while.

We understand that, unfortunately, this situation same does not prevail with the cores and frames coated with Hard Chrome. As I have explained, when the layer of chrome disappears of these elements, the wear of the piece significantly increases, and a new chrome coating process is necessary. This forces the manufacturer to have numerous spare parts on hand so as not to stop production.

From our perspective, this is a handicap, leading us to conclude that Hard Chrome technology is now obsolete, given that, in addition to not having the same performance as Treated Steel in matters of setting ups and the development of new products, it cannot compete in terms of durability and wear-resistance with tungsten carbide, leaving it in no man’s land.