THE SDMED PROJECT. (Smart Design and Manufacturing of Extrusion Dies)

MORTE has been working in the SDMED (“Smart Design and Manufacturing of Extrusion Dies”) project for several years within its ongoing improvement program and aligned with its R&D&i strategy. This project has allowed us to take a quantum leap forward, not only in the areas of design and manufacture of dies, but has resulted in something even more important: improved profitability for our customers.

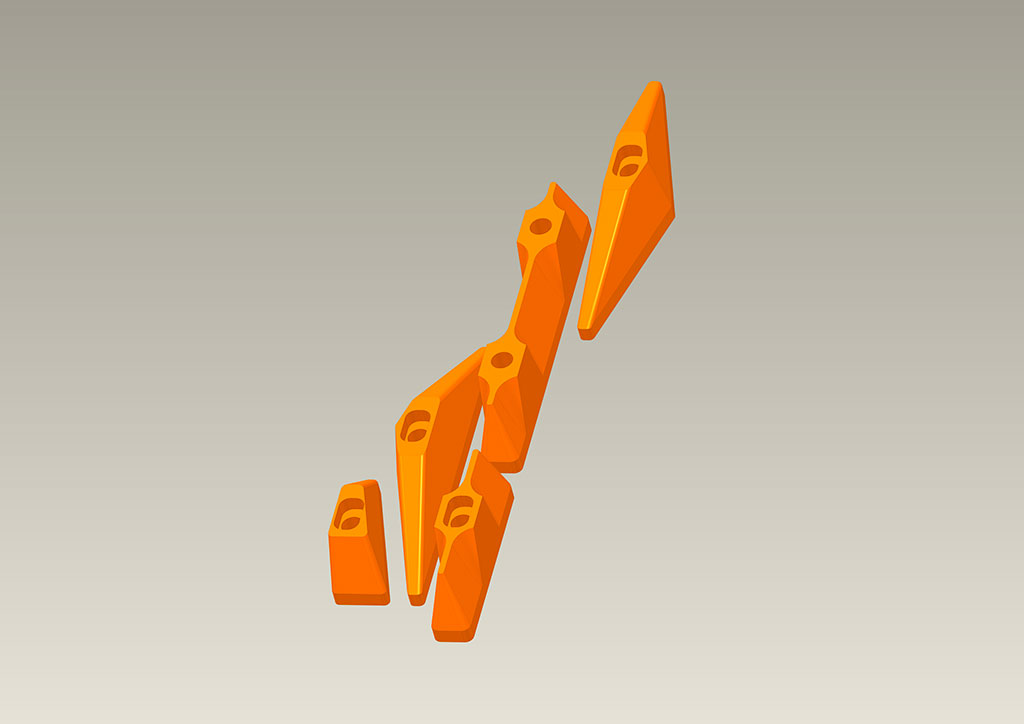

The manufacturing process of a ceramic extrusion die is an extremely complex task because of the variety of components it consists of, since a 150 core set may include over 20 references of different parts with complex geometries and very short or virtually nonexistent production runs, which means managing the design and production of each of them differently.

Through the SDMED Project, MORTE has analyzed the whole design and manufacture process of the different parts the die consists of, thus verifying aspects such as:

- Suitability of the machinery used in the manufacture of each of the parts.

- Analysis of the different cutting conditions of each tool used.

- Comparing the efficiency of machine programming vs programming from the Technical Office.

- Optimization of machining routes.

- Search for alternatives for the systems used to fasten parts onto the machine.

- Study the part reference and replacement systems.

- Control of tools.

During the past 18 months, numerous machining processes have been analyzed and measured and there have been intense work sessions in which most of MORTE ’s staff have taken part.

After carefully considering the matter, a series of actions that have transformed the way we work were implemented in stages and this resulted in:

- A reduction in the time required for machining cycles for the components of the die.

- Implementation of new systems for handling and fastening parts.

- Optimization of machining times.

- Increased flexibility of the machinery of the company.

- Better use of existing resources (machinery), which leads to an increase in production capacity.

- Improved quality of customer service

The implementation of this project has meant MORTE has improved its efficiency through an optimization of the work systems. But above all, it has turned MORTE into an increasingly efficient organization, more and more committed to improving its customers’ competitiveness and profitability.