We have welding wire, electrodes, tungsten carbide and other accessories to coat different clay preparation machinery components, such as screw propellers and blades for mixing and extrusion.

A wide range of items can be provided according to the specific needs of each customer and the function of the component to be coated.

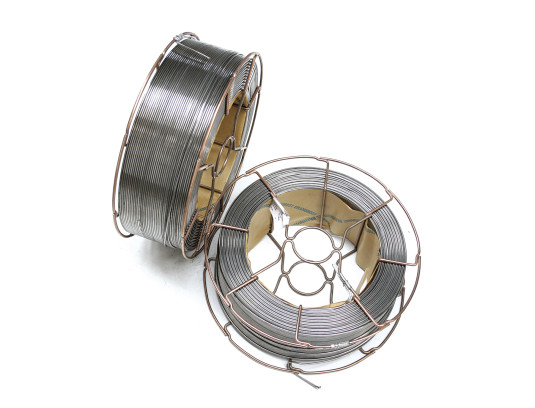

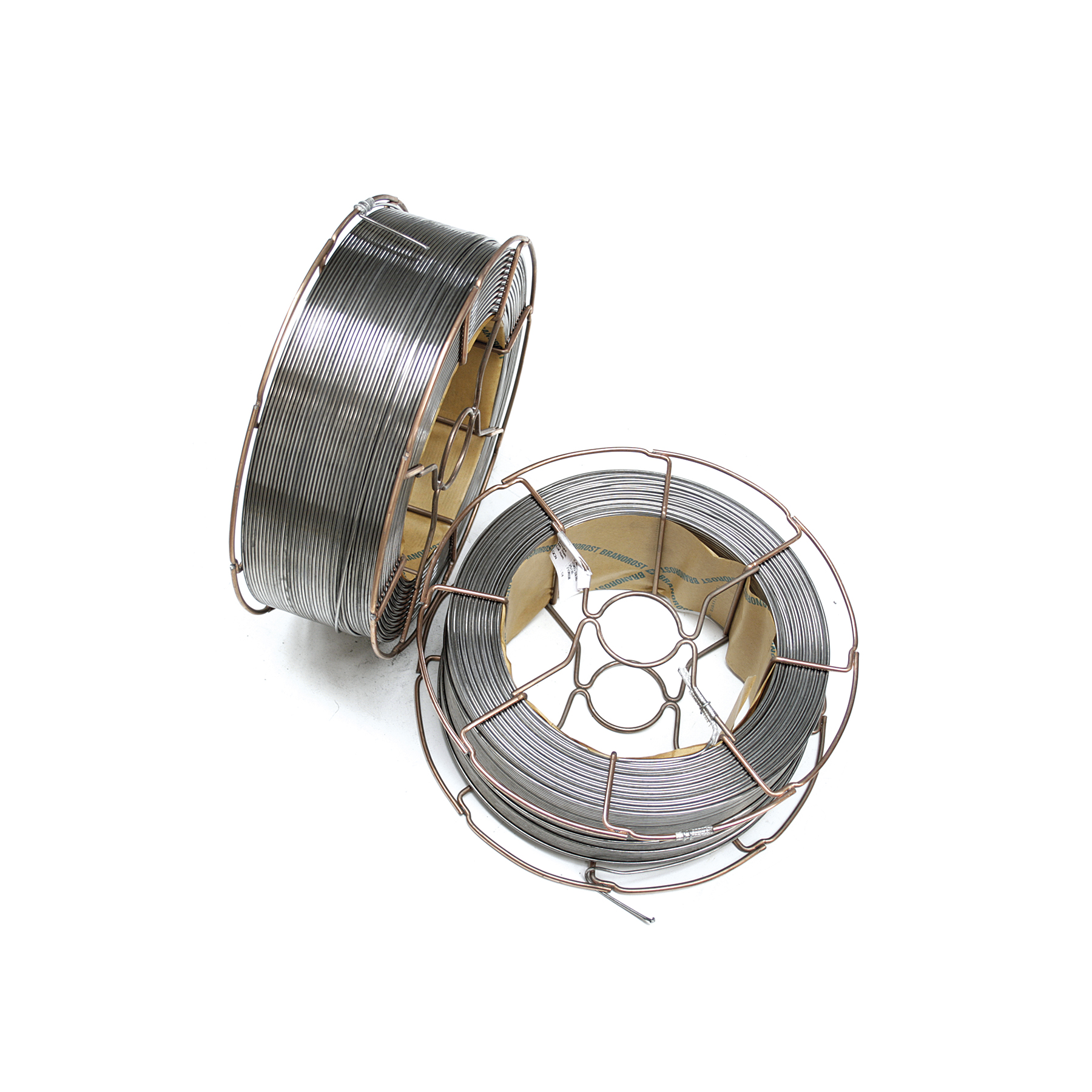

DESCRIPTION:

- High chromium carbide alloy designed to resist high stress grinding abrasion,resistant up to 450 º C

- 61 – 65 Hrc

- 1,6 and 2,4 mmØ

- Wheel of 15 kg

FEATURES:

- High platingspeed

- Can be used for one layer welding without higher hardness lost.

- Suitable for wearfacing , grids, augers, sholves, roller mills, crushers,etc.

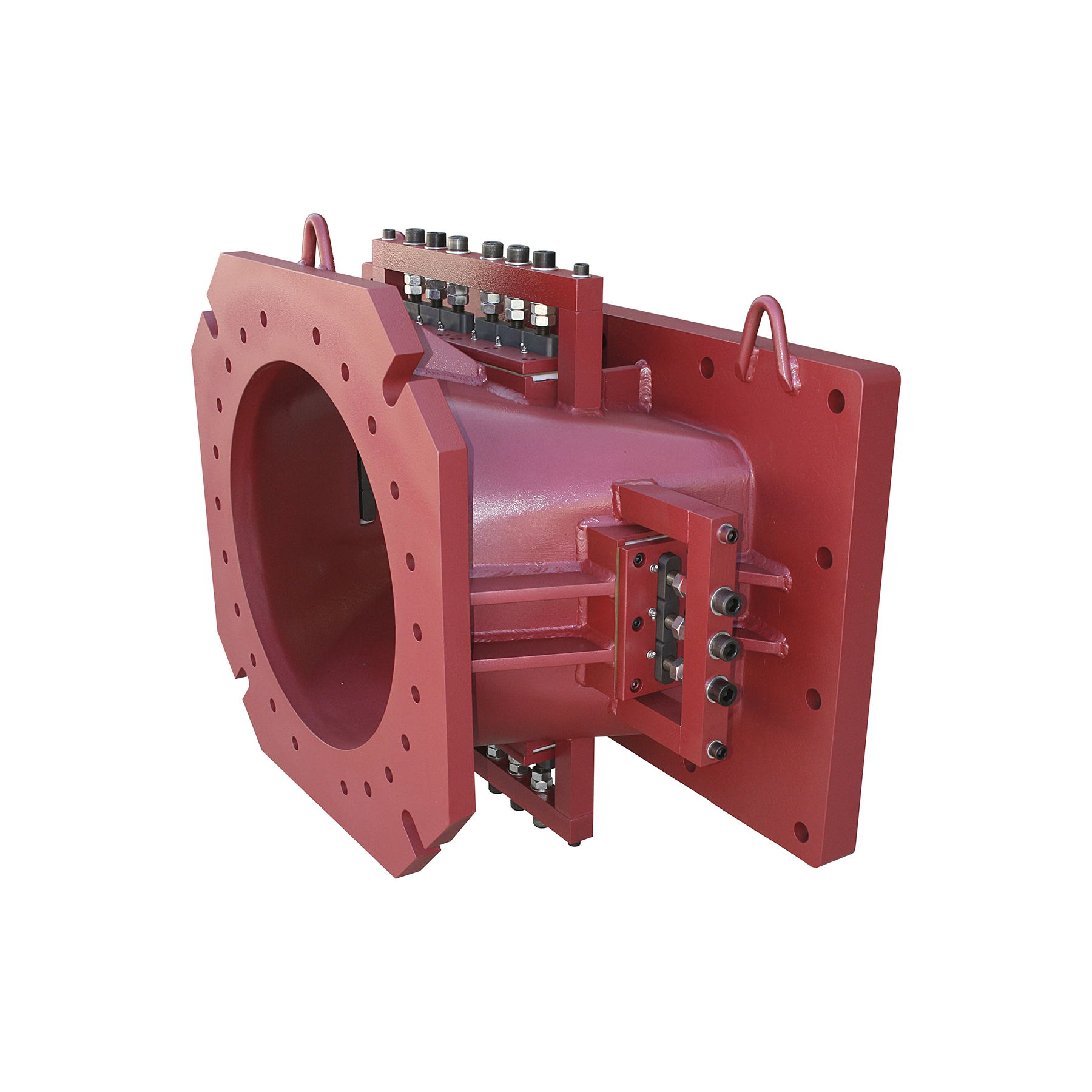

DESCRIPTION:

- High alloy content and carbide forming elements electrode with rutile-basic coating.

- 3,2 mm Ø.

- 61 – 65 Hrc.

FEATURES:

- Resistant up to 500ºC.

- Easy to weld, imperceptible slag, approximate yield of 190%.

- Suitable for joining and reconstruction of manganese steels and those with high sulphur and phosphorus content. Also for different unions between construction steels and stainless and for previous layers to hardfacing.

- Recommended for coating of elements subject to severe abrasion, friction, temperature and corrosion such as augers, mixing blades, razors and excavator blades for the ceramic industry

It can be supplied as:

ELECTRODE

- Tubular electrode extremely abrasion resistant, composed essentially of tungsten carbide in iron base matrix.

- Designated essentially for pieces that must resist severe abrasion in ceramicworks, mines and so on.

- Box of 5Kg.

THREAD

- Thread of tungsten carbide

- Base Ni y base Fe.

- 5- 6 mmØ.

- Wheel of 20 kg.

POWDER

- Fused tungsten carbide (crushed particles) allied with Ni-Cr-B and Si.

- Powders for oxy-acetylene torch deposition welding.

- 1 Kgplasticpot.

TECHNOKIT T2000 TORCH CASE

- It has a powder feeding system which uses the simultaneous spray-fuse technique.

- Great manageability. The length of the guns makes flame welding more comfortable by keeping the user’s hands away from hot areas.